Petrobras started the licensing process for the Auri robot, Autonomous Underwater Riser Inspection, a technology patented and developed by Petrobras in partnership with PUC-Rio. Equipped with high resolution cameras and remotely operated, the AURI is able to identify, with high precision, maintenance needs in the flexible pipelines that transport oil from subsea facilities to production platforms. As a result, it increases the safety and efficiency of operations, in addition to reducing operating costs. The tests were carried out on the P-43 platform, in the Campos Basin. The successful operation proved the effectiveness of the new robot, allowing the deployment and start of the technology licensing process, which should be completed by the end of the year.

“Petrobras created a broad program to increase safety in diving operations, called the Diverless Synergy Program. This program introduced new systems, methodologies and technologies to increase the safety of divers. The results we have obtained are an example of how a culture of innovation and overcoming generates value for the business, demonstrating that it is possible to produce more and more safely” informs the director of Production Development, João Henrique Rittershaussen.

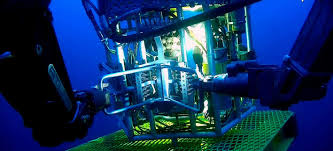

The robot is installed on the outside of the flexible submarine duct with the support of an ROV (Remote Operated Vehicle) and, from there, it performs part of the inspection tasks and all the cleaning, being operated, from the vessel, by a specialized professional. Another advantage is the ability of the robot to carry tools and rotate 360 degrees around the duct, even if it is very close to the platform hull, in a place that is difficult to access.

Currently, the tools used to clean the ducts are attached to the ROVs during the entire operation and, after that, the ROV still needs to be used to do the visual inspection. In the case of the AURI, the ROV is used only for its installation and uninstallation in the duct, being released for other activities in the rest of the time. The AURI also records videos of the inspected region for analysis and archiving of the images, which allows the evaluation of the pipeline by the teams that are on land.

“AURI is one of the robots being developed by Petrobras that are the result of the company’s constant investment in innovation. There are new developments to expand AURI’s functionalities, which will add even more value to the tool and expand the possibilities of gains and advances for the oil industry”, highlights the company’s Digital Transformation and Innovation director, Juliano Dantas.

Safety and Efficiency

The AURI robot has the potential to save more than 1,300 hours of diving operations, contributing to the safety of professionals. It was developed from the challenge of automating the cleaning and visual inspection of flexible pipelines, including in water depths greater than 30 meters, where diver time is reduced. The AURI reaches up to 50 meters without limitation of hours and, comparatively, presents a performance – reduction of cleaning time – greater than other tools transported by ROV during cleaning and inspection activities. Another advantage is that the AURI can be used even in adverse weather conditions, which are an obstacle to divers’ activity.

The robot can be manipulated and installed in flexible ducts to carry out cleaning at up to 10 times greater speed than is currently done, with consequent cost savings. With so many abilities, the robot already arouses the interest of companies providing this type of service. They wait for the end of the licensing – the process of authorization for commercial use – to have access to the technology.

Innovation

Petrobras will allocate around US$1.6 billion in its 2022-26 strategic plan for Digital Transformation and Innovation. Last year the company broke the national record with 119 patent applications, a mark that has not been surpassed since 2014. The Brazilian company is also the one that holds the most active patents in the country, 1035, and was the grand winner of the ANP Award for innovation 2021, taking first place in three of the five categories. The award recognizes the results of research, development and innovation (RD&I) projects that represent technological innovation of interest to the oil, natural gas and biofuels sector.

Leave a comment